一、主要技術規格Main specifications

|

原材料要求Material requirement |

適用材料Applied materials |

熱軋或冷軋,低碳鋼,Hot rolled or cold rolled, low carbon steel,Q235 |

|

材料質量Material quality |

正品鋼卷 Authentic steel coil |

|

|

材料力學性能Material mechanics performance |

抗拉強度Tensile strengthδb≤500Mpa, 屈服強度The yield strengthδs≤250Mpa |

|

|

原材料寬度width of raw material |

300mm~1250mm |

|

|

原材料厚度Thickness of raw material |

0.8mm~4.0mm |

|

|

鋼卷內徑 Coil I.D |

Ф508mm,φ610mm (根據用戶鋼卷確定According to user steel coil) |

|

|

鋼卷外徑 Coil O.D |

≦Ф1500mm |

|

|

鋼卷重量Coil Weight |

≦20噸Ton |

|

|

成品參數 |

鋼卷內徑 Coil I.D |

Ф508mm(可根據客戶要求定制)(Custom-size) |

|

鋼卷外徑 Coil O.D |

≦Ф1800mm |

|

|

鋼卷重量 Coil Weight |

≦20噸Ton |

|

|

縱剪能力 Longitudinal shear capacity |

0-10條pcs 根據客戶需求定制 according to Customer Require change. |

|

|

縱剪速度Slitting speed |

0-100m/min |

|

|

單側邊絲寬度Single side wire width |

≥2.5mm(板厚thickness 0.8mm-2.0mm時) |

|

|

≥3mm(板厚thickness 2.01mm—4.0mm時) |

||

|

邊絲要求 Edge silk requirements |

必須兩側都要有邊絲 Must have the edge silk on both sides |

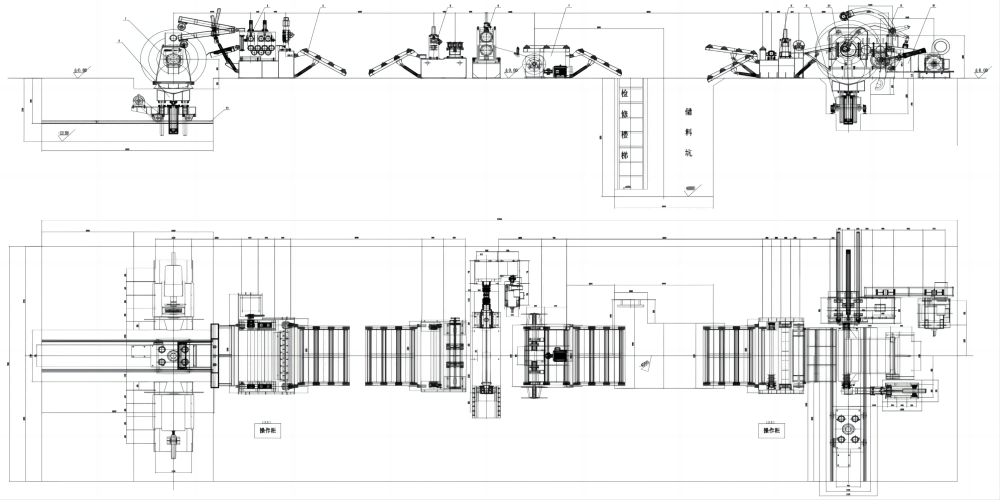

二、工藝流程process flow

開卷uncoiler→矯平Straighten→剪切Shear→導向對中guide→縱剪Slitting→分條壓料Article→收卷 Recoiler

三、設備主要參數與配置Main equipment parameters and configuration

|

主要部件驅動電機The drive motor Of the main components |

上料小車Feeding Car |

2.2KW |

1臺pcs |

|

輔助開卷Auxiliary uncoiling |

4KW |

1臺pcs |

|

|

夾送與矯平機Clip with leveler |

18.5KW |

1臺pcs |

|

|

縱剪主機Slitting host |

75KW |

1臺pcs |

|

|

上刀軸壓下電機Knife shaft under pressure |

2.2KW |

1臺pcs |

|

|

廢絲收圈機Waste silk collect machine |

3KW |

1臺pcs |

|

|

收圈主機collect host |

132KW |

1臺pcs |

|

|

卸料臺車Discharging car |

2.2KW |

1臺pcs |

|

|

液壓站Hydraulic station |

11KW |

1臺pcs |

|

|

裝機容量 installed capacity |

約about 250KW |

||

|

電源Power |

380V/50Hz/3ph |

||

|

縱剪速度 sliting speed |

0-100m/min(無級調速Stepless speed regulation) |

||

|

縱剪方式type |

拉剪形式pullshear form |

||

|

電柜配置 Electric cabinet configuration |

控電柜Control electrical cabinet |

||

|

主操柜The main operating ark |

|||

|

副操柜Deputy operating ark |

|||

|

設備生產方向Equipment production direction |

客戶定(人在操作臺,面向機組看)(custom-size) |

||

|

設備占地面積Equipment cover area |

約長25米×寬8米 about 25Mx8M |

||

|

生產操作人員 Production operators |

技術工1人 輔助工2-3人1 technician backup 2-3 people 注:具體生產操作人員數量客戶可根據設備生產現場實際情況決定。Specific production operation personnel quantity customer can according to the actual situation of equipment production site. |

||

|

設備顏色 Equipment color |

可按客戶需求制作Custom-size |

||

四、縱剪分條機組單機設備的功能參數Slitting article points the function of the single unit equipment parameters

1、雙頂錐式液壓開卷機(含上料小車)Double top cone type hydraulic uncoiler(within feeding car)

|

功能function |

采用錐形雙向頂緊結構形式,帶機械式剎車阻尼機構控制張力開卷,隨縱剪主機的速度平穩放料。The taper two-way top tight structure, with the mechanical brake damping control tension decoiling, along with the speed of slitting the host smooth feeding |

|

構造structure |

由開卷架與卷筒組成。鋼板與型鋼焊接而成開卷架;卷筒則由中心長軸與扇形板組成。Is composed of uncoiler rack and the drum. Steel plate and steel welded together open book; Drum is the center of long axis and the fan-shaped plate. |

|

設計最大掛料Biggest hanging design |

≦20噸Ton |

|

適應頂緊鋼卷內孔To adapt to the top tight hole steel volumes |

φ508mm |

2、液壓自動放料,引頭,鏟頭裝置Hydraulic automatic feeding, head, shovel head device

|

功能function |

通過自身主動放料和液壓鏟頭裝置作用,把帶頭安全,平移,送入牽引夾送初矯機內。Through their own feeding and hydraulic shovel head device, to take the lead in security, pan, into the early traction pinch machine. |

|

功率power |

BWED52-187-4KW |

|

構造structure |

鋼板和型鋼焊接而成Steel plate and steel welded together |

3、牽引夾送矯平機Traction pinch leveler

|

功能function |

用于將鋼卷板平面矯平后送入后序加工。夾送輥與矯平輥上下調整采用液壓缸來控制。Used for steel plate surface leveling roll into after order processing. Pinch roll and leveling roll adjustment adopts hydraulic cylinder to control up and down. |

|

動力power |

18.5KW |

|

構造structure |

兩支夾送輥與五支矯平輥墻板、電機、減速機及機架等組成。Two pinch roll and five leveling roll wallboard, motor, reducer and racks, etc. |

|

夾送輥直徑φ180mm表面中頻淬火、磨加工。矯平輥直徑φ150mm,表面中頻淬火,磨加工。Pinch roll diameter phi 180 mm medium frequency quenching, grinding surface. Leveling roll diameter of 150 mm, surface intermediate frequency quenching, grinding. |

4、前過渡導料滾道臺Frontmaterial transition guide groove

|

功能Function |

引導板料順利進入縱剪主機。Lead thestrip into slitting host. |

|

構造Structure |

采用100mm×100mm×厚度4.75mm的方管與400mm×120mm×厚度3mm冷彎型鋼焊接組成。Using 100 mm * 100 mm * 4.75 mm thickness of square pipe with 120 mm * 400 mm * 3 mm thickness of cold bending steel welding. |

|

工作臺面滾筒直徑φ100mm,有效工作輥面長度1450mm。Work surface roller diameter of 100 mm, effective work roll surface length is 1450 mm. |

|

5、導向對中裝置Orientation of the device

|

功能Function |

引導卷板料順利進入縱剪主機,并且使板料中心與縱剪主機中心保持一致,消除跑偏現象,提高成品質量。Guide roll sheet smoothly into the slitting host, and make the sheet metal center and slitting hosts, eliminate the phenomenon of running deviation, improve the quality of the finished product. |

|

構造Structure |

By the guide frame, dovetail refined guide, a guide roller, copper spirit, adjust the screw, sliding seat, hand wheel, etc. |

6、縱剪主機slitting host

|

功能Function |

將鋼卷縱向剪切成需要的寬度。通過調換隔套,可靈活改變剪切成品寬度。采用液壓側開機架,更換刀片方便。 The width of the longitudinal shear steel coil into need. Through changing spacer, flexible change shear finished width. The hydraulic side on frame, easy to replace the blade. |

|

動力Power |

75KW直流調速電機。Dcspeed controlmotor |

|

動力部分構造Dynamic part of the structure |

由機座、減速機、對齒箱、十字萬向軸等組成 By the stand, deceleration machine, the gearbox, cross cardan shaft, etc |

|

縱剪部分構造Slitting part structure |

由刀軸牌坊、刀軸滑塊、刀軸軸承、推力座等 組成,刀軸材質40cr,軸徑Ф220mm調質處理后精磨加工; Slider by the knife shaft memorial arch, knife shaft, such as the knife shaft bearing, thrust, 40 cr knife shaft material, diameter of axle Ф 220 mm conditioning treatment after fine grinding; |

|

縱剪刀片材質slitting knife material |

6CrW2Si,Ф350×Ф220×15mm ,12片pcs。 |

|

橡膠墊圈The rubber gasket |

Ф346mm×Ф280mm ,(厚薄均勻搭配),套滿刀軸(thickness even match), set of knife shaft |

|

刀軸襯圈Knife brass ring |

Ф280mm×Ф220mm ,(厚薄均勻搭配),套滿刀軸(thickness even match), set of knife shaft |

7、邊絲收卷機edge silk Recoiler

|

功能Function |

位于生產線二側,用途在于縱剪機將鋼卷分條后,利用該裝置將兩條廢邊絲纏繞成卷狀。 In the production line two side, purpose is to after steel coil slitting machine, slitting machine using the device will be two waste silk winding roll shape. |

|

特點characteristics |

在正常生產過程中,邊絲收卷機始終收緊兩條邊絲,并能自動跟蹤縱剪主機速度使操作工專心于縱剪成品質量,提高工作效率。 In the normal production process, always tighten the two filament winding machine and wire, and can automatically track the slitting host speed make the operator to concentrate on slitting finished product quality, improve the work efficiency. |

|

功率Power |

3KWTension motor |

|

構造structure |

由底座、力矩電機、減速機、卷料軸、廢料門等組成。 By the base, torque motor, deceleration machine, coil axis, the waste gate, etc. |

8、后過渡導料滾道臺After the transition material guide groove

|

功能Function |

引導縱切后的成品板料順利進入收卷主機。 Boot after slitting finishedstrip into the host |

|

構造structure |

采用100mm×100mm×厚度4.75mm的方管與400mm×120mm×厚度3mm冷彎型鋼焊接組成。 Using 100 mm * 100 mm * 4.75 mm thickness of square pipe with 120 mm * 400 mm * 3 mm thickness of cold bending steel welding. |

|

工作臺面滾筒直徑φ100mm,有效工作輥面長度1450mm。 Work surface roller diameter of 100 mm, effective work roll surface length is 1450 mm. |

|

9、預分料壓料張力阻尼裝置Preassigned pressure material tension damping device

|

功能Function |

前端分離器把剪出的成品預先隔開,帶阻尼張力后再收卷成平整的圈狀。Front-end separator separates cut out of finished products in advance, after the belt tension of damping winding into flat circle shape again. |

|

構造structure |

由牌坊、上下張力輥、同步軸、油缸、底座等組成。 By the memorial arch, the tension roll up and down, synchronous shaft, oil cylinder, base, etc. |

|

分離片規格Ф250×Ф115 材質65Mn ,厚度6mm ,12片。 Separate sheet specifications Ф 250 x 115 Ф material 65 mn, thickness of 6 mm, 12 pieces |

|

|

分離片襯圈Ф165×Ф115 (材質:45#鍛件,厚薄均勻搭配)套滿分離主軸。 Separation sheet lining Ф 150 x 115 Ф (material: 45 # forging, thickness even match) set of spindle full separation |

|

10、液壓分條壓料裝置與收卷主機Separated hydraulic pressure device and theRecoiler host

|

功能Function |

將縱切后的鋼帶分離并收成帶卷,帶卷由下料臺車運出。卷筒采用直流電機驅動旋轉,液壓驅動徑向漲縮方式。液壓懸臂式帶卷分離器可隨鋼卷增大而自動上升,并能始終壓緊鋼卷。帶氣動剎車裝置。 Separate the steel strip after slitting and harvest coil, coil car by cutting out. Drum driven by dc motor rotation, hydraulic radial increases. Hydraulic cantilever coil separator can be automatically rise with the increase of steel coil, and the and can always compression steel coil. With pneumatic brakes. |

|

構造structure |

收卷部分由機座、活套、軸承座、齒輪離合器、油壓推板、支撐座隔套等組成;Recoiler part consists of frame, looping, bearing, gear clutch, hydraulic push board, brackets bushing, etc |

|

功率Power |

132KW直流電機DC motor; |

|

收卷成品內孔φ508mm(可根據客戶要求定制)Recoiler the finished inner hole phi 508 mm.(custom-size) |

|

|

最大收卷重量為15噸MaximumRecoiler weightis 15 tons |

|

11、收卷輔助支撐座Winding auxiliary brackets

|

功能Function |

為收卷主軸減輕承重負荷,使主軸承重均勻,減少主軸變形。For winding spindle reducing load bearing, the spindle bearing uniform, reduce the deformation of the spindle. |

|

構造Structure |

由座架、油缸、支架、擺臂、軸銷等組成。By the saddle, oil cylinder, stents, swing arm, axis pin, etc. |

12、液壓下料臺車Hydraulic cutting car

|

功能Function |

升降及水平移動將收卷的成品圈料從收卷主軸上安全卸下打包。Lifting and horizontal movement, the winding circle of finished material discharged from winding spindle on safety packaging. |

|

構造Structure |

鋼板與型鋼焊接而成。Steel plate and steel welded together. |

|

功率Power |

行走電機Walking motor BWED42-121-2.2KW。 |

|

設計最大舉升噸位為20噸。Design maximum lifting capacity of20 tons |

|

13、液壓總站hydraulic station

|

功能Function |

本生產線的液壓系統有一臺液壓站和相應的泵、閥、管路組成,提供液壓動力。This production line of hydraulic system with a hydraulic station and the corresponding pump, valve, pipe.provide hydraulic power |

|

功率Power |

11KW |

|

系統壓力12MPa,工作壓力6-8MPa。(可單獨調壓)The system pressure 12 mpa, 6-8 mpa pressure of work. (can be regulating alone) |

|

14、電器控制系統與操縱系統Electrical control system and control system

|

主要元件采用國外或國內名牌產品。 The main components adopt foreign or domestic famous brand products. |

|

配備前、中、后3套操縱箱,以主操作柜為主操控整套設備的正常運行,各操縱柜之間都設有互相聯動與互鎖功能。With before, during and after 3 sets of control box, to the main operating ark is given priority to control the whole equipment normal operation, between various control cabinets have mutual linkage and the interlock function. |

15、設備潤滑系統Equipment lubrication system

在整套設備各部件都設有相應的加油提示、人工加油和黃油咀等I

n the whole equipment parts have corresponding artificial refueling tips, and butter nozzle, etc。

16、安裝及調試Installation of the equipment

1. 設備基礎部分及相關配套設施由需貨方負責。

The seller will provide the buyer the foundation ichnographies of the equipment.

2. 供貨方負責指導安裝調試。

The construction and monitoring of all the foundation engineering of the equipment are in the control of the buyer.

3. 現場安裝所需材料由需貨方負責。

All the installation material is supplied by buyer.

4. 安裝調試期間路費、食宿由需貨方負責。

The cost from transportation and hotel is covered by the buyer.

六、縱剪分條機組設備組成equipment list

|

液壓錐形雙夾掛料開卷機(含上料小車)Hydraulic cone double clip hangingUncoiler (including feeding small car) |

1套 pcs |

|

輔助開卷壓頭Auxiliary uncoiling pressure head |

1套pcs |

|

鏟板裝置Shovel plate device |

1套pcs |

|

矯平剪切機Leveling shearing machine |

1套pcs |

|

前過渡導料滾道臺Front material transition guide groove |

1套pcs |

|

導向對中裝置Orientation of the device |

1套pcs |

|

縱剪主機Slitting Host machine |

1臺pcs |

|

邊絲收卷機silk Recoiler |

1臺pcs |

|

后過渡導料滾道臺Behindtransition material guide groove |

1套pcs |

|

預分料壓料阻尼裝置Preassigned pressure material damping device |

1套pcs |

|

液壓分條壓料裝置Separated hydraulic pressure loading device |

1套pcs |

|

收卷主機Recoiler Host Machine |

1臺pcs |

|

收卷輔助支撐座RecoilerAuxiliary brackets |

1套pcs |

|

液壓下料小車hydraulic car |

1臺pcs |

|

液壓系統hydraulic system |

1套pcs |

|

電氣控制柜Electrical control cabinet |

1臺pcs |

|

主操作柜main operation counters |

1臺pcs |

|

副操作柜deputy ark |

1臺pcs |

Our main products are: open-book machine, shearing machine, spiral looper, precision welded pipe forming equipment, is a research and development, design, production, sales as one of professional manufacturers.

Our main products are: open-book machine, shearing machine, spiral looper, precision welded pipe forming equipment, is a research and development, design, production, sales as one of professional manufacturers.